Stainless steel screws have good mechanical properties such as anti-rust, anti-corrosion, high temperature resistance.

Stainless steel self tapping screw mainly used for: environmental protection equipment, medical equipment, communication equipment, power facilities, electronic products, instrumentation, food machinery, pump valve pipeline, building curtain wall, sports facilities, outdoor decoration.

King Tower specializing in the production of various non-standard stainless steel screws. The thread diameter, length, and head type all according to customer requirements.

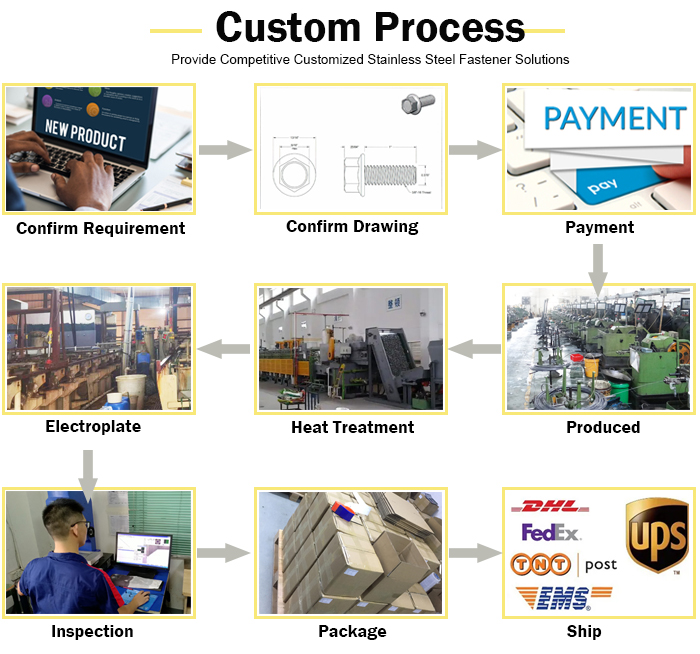

King Tower Focus on Every Custom Stainless Steel Screw Process

Why Choose King Tower

King Tower provide SGS / RoHS / Raw Material report, and get ISO9001:2015 / IATF16949:2016 certificate.

FAQs for Stainless Steel Screw

Q: What are the standard grades of stainless steel screws?

A: A2 is the most common grade (classic 18/8) and is also known as “type 304”. A4 is the second most common and is known for its high resistance to corrosion.

Q: What is stronger: zinc or stainless steel screws?

A: Stainless steel screws are usually stronger than steel screws. Steel screws also rust more easily.

Q: When do you use stainless steel screws?

A: Stainless steel screws are most commonly used when reliable weather, water and corrosion resistance are required.

Q: What are the surface treatments of stainless steel screw?

A: Electroplating, Passivated, Polished and Sandblasting.

Q:Are stainless steel screws magnetic?

A: 304 stainless steel material is weak magnetic.